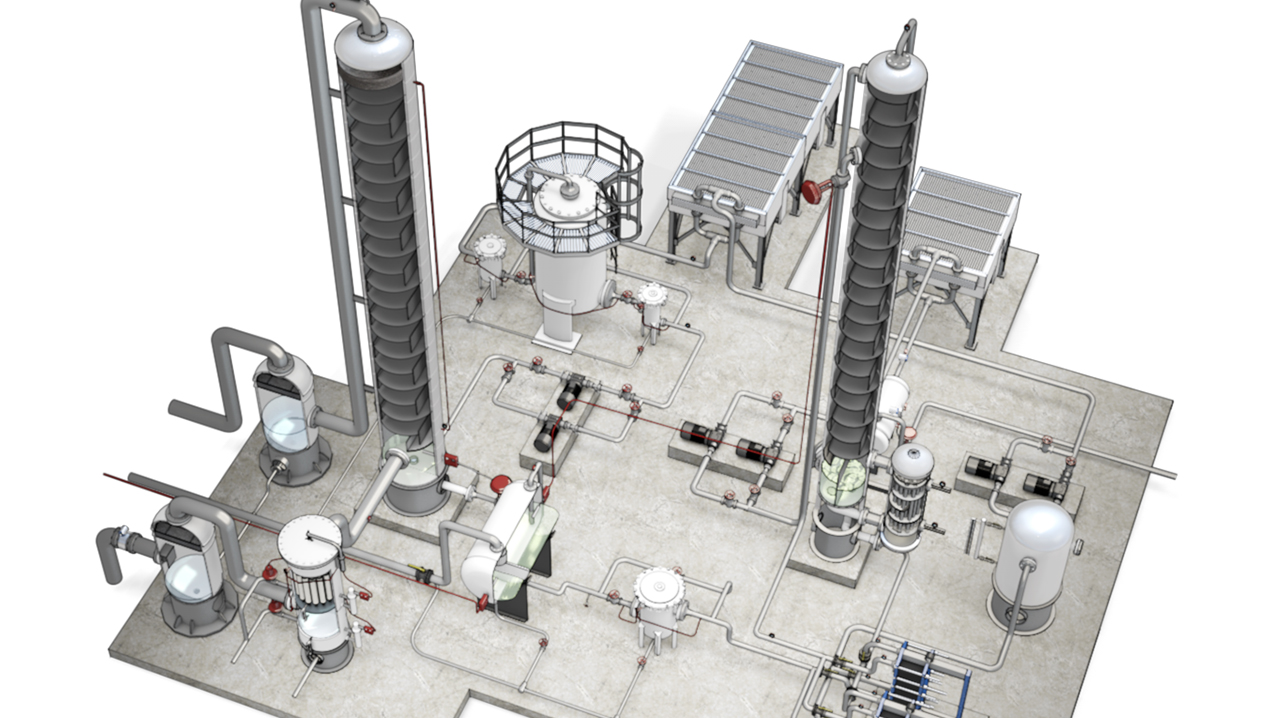

Amine Acid Gas Removal - Intermediate

Covers the most common troubleshooting issues such as foaming, corrosion, and difficulty meeting H₂S and CO₂ specifications, and explores the root causes and treatments for these problems. Includes details on tail gas treaters and acid gas enrichment.

Course Price

600

Content

1.0 Alternative Amine Treating

1.1 Liquid-Liquid Treating

1.2 Liquid-Liquid Testing

1.3 Liquid-Liquid Operating Parameters

2.0 TGTU

2.1 Flowsheet

2.2 Quench Column

2.3 TGTU Absorber

2.4 TGTU Regenerator

2.5 TGTU Operating Parameters

3.0 Acid Gas Enrichment

4.0 Amine Solution Analysis

4.1 Amine Appearance

4.2 Amine Testing

4.3 Loading Analysis

4.4 Foam Test

4.5 Heat Stable Amine Salts

4.6 Metal Scans

4.7 Total Suspended Solids

4.8 Other Tests

4.9 Reflux Water Test

4.10 Test Frequency and Procedures

5.0 Meeting Specifications

5.1 H₂S and CO₂ Specifications

5.2 Lean Loading

5.3 Lean Amine Temperature

5.4 Contact problems

5.5 Contactor Fouling

5.6 Hydraulic Issues

5.7 H₂S Spec Checklist

6.0 Meeting CO₂ Specifications

6.1 CO₂ Slip and Removal

6.2 Amine Specifications for CO₂

6.3 Contactor Inlet Points

6.4 Meeting CO₂ Specifications

7.0 Amine Loss

7.1 Vapourization

7.2 Solubility

7.3 Entrainment

7.4 Foaming

7.5 Foaming Symptoms and Causes

7.6 Polar Hydrocarbons

7.7 Foaming Troubleshooting

7.8 Anti-Foam 1

7.9 Anti-Foam 2