MEG Refrigeration - Intermediate

Provides a base overview of process principles of liquid desiccants and basic plant chemistry, and a general equipment overview and process run-through for the entire monoethylene glycol (MEG) refrigeration process.

Course Price

400

Content

Tartan Academy Instructions

1.1 Hydrate Formation & Control Methodologies

1.2 Gas Hydrate Structures & Formation Composition 1

1.3 Gas Hydrate Structures & Formation Composition 2

1.4 Effect of Gas Composition on Hydrate Formation

2.1 Hydrate Control Methods - Chemical Inhibition 1

2.2 Hydrate Control Methods - Chemical Inhibition 2

2.3 Hydrate Control Methods - Liquid Desiccants

2.4 Hydrate Control Methods - Heat Application

3.1 Process Principles Liquid and Solid Desiccants

3.2 Water Content Calculation 1

3.3 Water Content Calculation 2

3.4 Dewpoint Depression

3.5 Dewpoint Analyzers

4.1 Different Types of Glycols

4.2 Applicable Uses for MEG

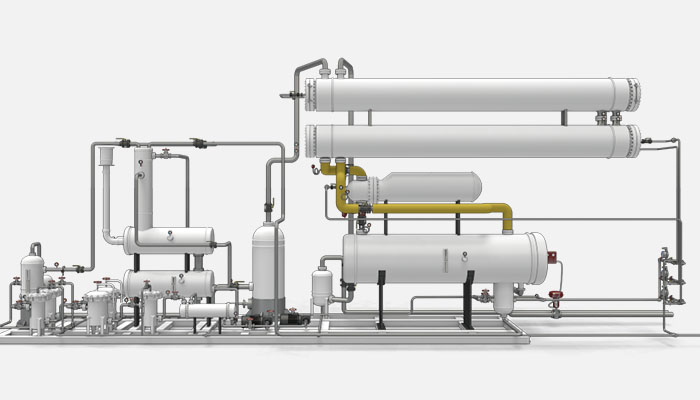

5.1 Refrigeration Process Equipment Overview 1

5.2 Refrigeration Process Equipment Overview 2

5.3 Inlet Separator

5.4 Gas/gas Exchangers

5.5 Propane Chiller

5.6 JT Valve

5.7 Low Temperature Separator 1

5.8 Low Temperature Separator 2

5.9 Reflux Coil

5.10 Flash Tank

5.11 Particulate Filters

5.12 Activated Carbon Cartridge and Bed

5.13 Lean-Rich MEG Heat Exchanger

5.14 Still Column

5.15 Reboiler

5.16 Glycol Accumulator or Surge Tank

5.17 Glycol Circulation & Injection Pumps

6.1 Injection Nozzle Considerations

6.2 Injection Nozzle Location

6.3 Injection Nozzle Selection

6.4 Injection Nozzle Wear

7.1 Summary